Material Characterization with Destructive and Non-Destructive Testing

Our Material Characterization team is dedicated to providing in-depth analysis of materials through both destructive and non-destructive testing methods. We adhere to established standards and regulations to ensure that our testing procedures yield reliable and comprehensive evaluations of material properties, performance, and integrity. Our expertise in these methodologies supports the development and validation of high-quality, durable products across a wide range of industries.

Comprehensive Testing Approach

We employ a balanced approach that integrates both destructive and non-destructive testing techniques, offering a thorough understanding of material characteristics:

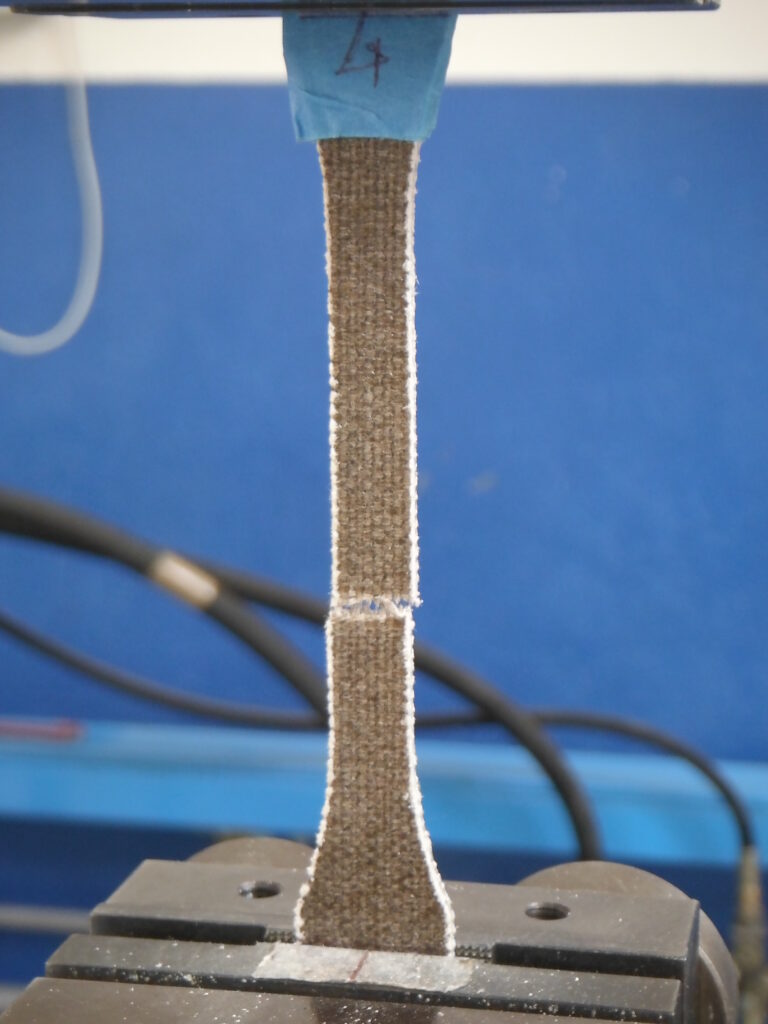

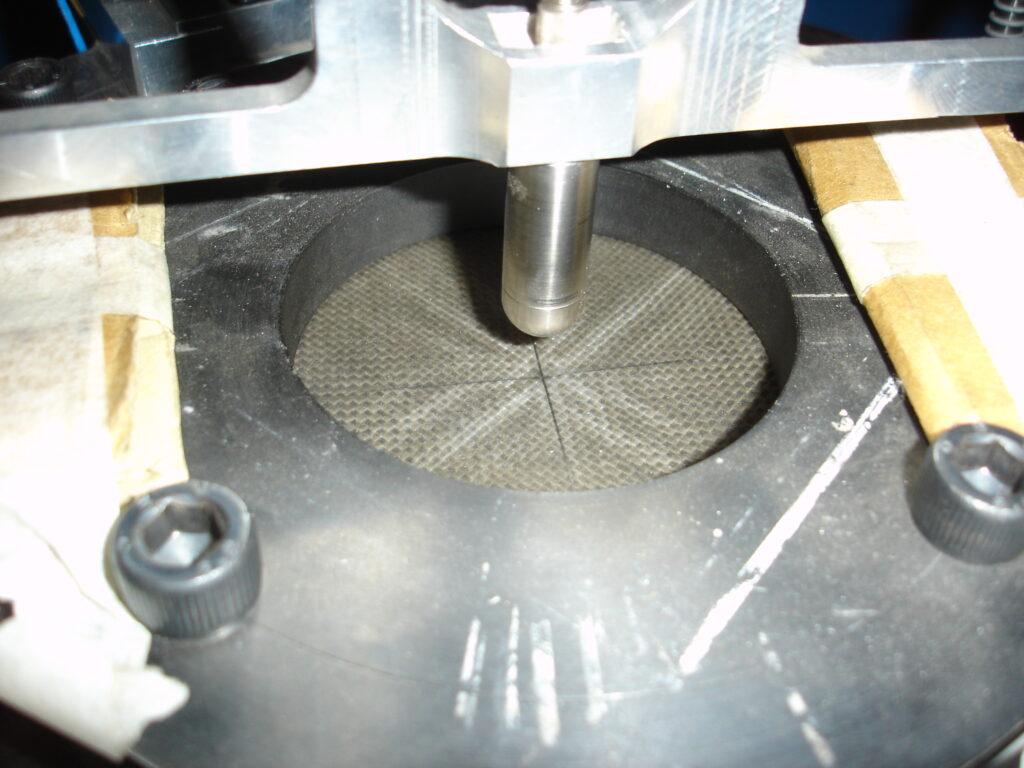

- Destructive Testing: This method involves subjecting materials to conditions that will cause failure or permanent deformation, allowing us to assess their ultimate strength, ductility, and other critical properties. Key destructive testing techniques include:

- Tensile Testing: Measuring the material’s response to axial loads, including yield strength, tensile strength, elongation, and reduction in area.

- Impact Testing: Evaluating the material’s toughness and resistance to sudden, high-impact forces using methods such as Charpy and Izod impact tests.

- Fatigue Testing: Determining the material’s durability and resistance to cyclic loading over time, which is crucial for components subjected to repetitive stresses.

- Hardness Testing: Assessing the material’s hardness through methods such as Rockwell, Vickers, and Brinell tests to determine its resistance to deformation and wear.

- Non-Destructive Testing (NDT): This approach allows us to inspect materials and structures without causing any damage, providing insights into their internal condition and performance characteristics. Common NDT methods include:

- Ultrasonic Testing (UT): Using high-frequency sound waves to detect internal flaws, such as cracks or voids, and to measure material thickness.

- Radiographic Testing (RT): Employing X-rays or gamma rays to produce images of the internal structure of materials, revealing imperfections and inconsistencies.

- Magnetic Particle Testing (MPT): Applying magnetic fields and particulate media to identify surface and near-surface defects in ferromagnetic materials.

- Dye Penetrant Testing (DPT): Utilizing liquid dye and a developer to reveal surface-breaking defects, such as cracks or porosity, through visible contrast.

- Eddy Current Testing (ECT): Using electromagnetic induction to detect surface and subsurface defects and to measure material properties, such as conductivity and thickness.

Detailed Analysis and Evaluation

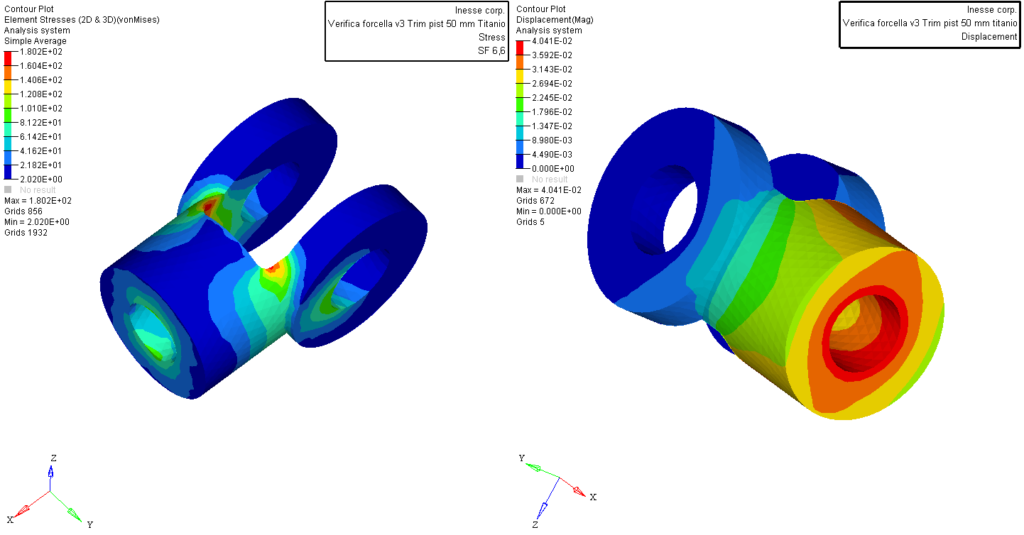

Our rigorous testing procedures provide critical insights into material behavior under various conditions. We perform detailed analyses to evaluate:

- Material Properties: Understanding fundamental properties such as strength, elasticity, hardness, and thermal resistance. These properties are essential for predicting how materials will perform in real-world applications.

- Performance Characteristics: Assessing how materials behave under different stresses, strains, temperatures, and environmental conditions. This helps ensure that materials will perform reliably in their intended applications.

- Integrity and Reliability: Identifying potential flaws, weaknesses, or inconsistencies in materials that could impact their performance and longevity. This is crucial for ensuring the safety and durability of components and products.

Compliance with Industry Standards

We adhere to established industry standards and regulations to ensure that our testing methods and results are accurate, reliable, and compliant. Our testing procedures are aligned with standards from organizations such as ASTM International, ISO, and ASME, among others. This compliance guarantees that our material characterizations meet the highest quality and safety standards.

Supporting Product Development and Validation

Our material characterization services play a critical role in supporting the development and validation of high-quality products. By providing detailed and accurate material data, we help our clients:

- Design Optimization: Make informed decisions about material selection and design modifications to enhance product performance and reliability.

- Quality Assurance: Validate that materials and products meet required specifications and performance criteria, reducing the risk of failure and ensuring customer satisfaction.

- Regulatory Compliance: Ensure that products comply with industry regulations and standards, facilitating market entry and reducing liability.

Innovation and Continuous Improvement

We are committed to staying at the forefront of material characterization technology. Our team continuously explores new testing methods, technologies, and advancements to enhance our capabilities and deliver the most accurate and reliable material analyses.

Client-Centric Approach

Our approach is centered around understanding and meeting the specific needs of our clients. We provide tailored testing solutions and comprehensive reports that address the unique requirements of each project, ensuring that our material characterizations support your objectives and contribute to your success.

In summary, our Material Characterization team offers a comprehensive analysis of materials through both destructive and non-destructive testing methods. By combining these approaches, we provide accurate and detailed characterizations that ensure reliability, performance, and compliance with industry standards. Our commitment to excellence supports the development and validation of high-quality, durable products across various applications.